Geopolitical issues in Myanmar make genuine Teak lumber buying very confusing. Previously, the serious buyer could always discount the lower quality lumber by determining the country of origin (e.g. India, Indonesia, Cote d’Ivoire – more on these in a future blog post), as it has long been known that Burmese Teak is the standard by which all others should be judged. Now, with Burmese Teak potentially being completely unavailable, the yacht or luxury home builder needs to look for some other factors to ensure that they are getting the best quality product. More importantly additional sources for Teak NOT sourced from Myanmar need to be understood and embraced.

Can You Get the Sizes You Need?

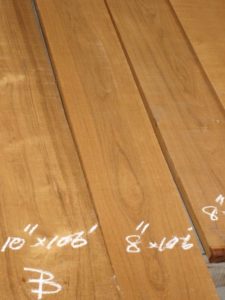

Teak is an odd product. It isn’t quite like an S4S dimensional product, but it also isn’t sold like rough sawn lumber. Usually it is sold in sizes closer to the finished product, so it has a wide variety of thicknesses, widths, and lengths, each with a price tag associated with it much like dimensional softwoods. However, Teak is rough sawn, and there is some leeway in the width and length like a rough sawn product sold in random width and length bundles.

The key is to ensure that you are getting the size you will need, while staying hyper vigilant over your overage. Teak is an expensive lumber, so every board foot counts. I’m not advocating buying exact amounts with no overage; however, recognize that price differences and quantities may vary, depending on the sizes you need.

If you can’t provide the specific dimensions which your project will require, then expect that the quote from your Teak dealer will be just as vague and likely to change. Moreover, if you get dramatic variance in pricing from two dealers, but you have supplied them both with specific size requirements, double check what each dealer is actually selling you. Price differences will occur, but massive price changes are usually red flags.

Has the Teak Been Re-Dried?

Exotic lumber that is kiln dried is almost 100% of the time dried to the wetter European standards of 12-15%. If you are using the Teak in an exterior situation where precision isn’t required (decks, docks, siding, etc), then this is probably your best option.

However, if the Teak is to be used inside or joined in a more precise manner – such as in yacht building – then it is best to have it re-dried to 6-8%, or you will face some major movement issues during the project build. Ask your dealer what the moisture percentage is for the material they are quoting. Obviously, re-drying adds production time and cost, but also some wastage.

The important thing to do is to work with your Teak dealer and make sure they know exactly how you plan to use the Teak. A good dealer will understand wood movement and be able to guide you to the right product. J. Gibson McIlvain, as a rule, re-dries our exotic lumber; however, we don’t re-dry in every case, because, as stated above, sometimes the higher moisture can be advantageous. If we can save a customer some money by not re-drying the Teak when it isn’t needed, then we want to reserve that option.

I’m purposely leaving out the physical appearance and grade of the Teak, as this is really a subject for its own article and can often lead to some questions about where the Teak actually comes from. Also, one has to recognize that Teak is a naturally occurring material, and variation in appearance will occur across even an order as small as 100 hundred board feet. Isn’t that difference really what makes Teak so beautiful in the end?

The takeaway from this is that you may very soon have a lot more choices from whom you buy your Teak. Educate yourself and work with your supplier to find the right match of material for your specific project.

Learn more about the lumber industry:

Leave a Reply