That depends (sigh)… How do you plan to use it?

What is Marine plywood used for?

Marine plywood is any plywood made to withstand the elements of nature, specifically water. So it is used for Marine construction like boats and docks but also water front properties. As you can imagine the amount of exposure the plywood sees varies widely on whether it is used on a boat or on an ocean front home. The particular use of the marine plywood will help dictate what exact product you should purchase.

Any call or email we get for marine grade plywood results in a series of questions about why it is needed and how it will be put to use. The term “marine grade” is used a bit too liberally by manufacturers to be trusted at face value. In other words there are many shades of gray to it and and most likely a good product can be found for your project whether it be exterior home work, a marina, or a boat. The standards required by APA- The Engineered Wood Association, for a product to be called “marine grade” are not that much higher than your typical exterior grade plywood. With many options for glue, veneers, plies, and preservatives to consider, close examination of what your final project will be subjected to must be considered before deciding which marine plywood product to buy.

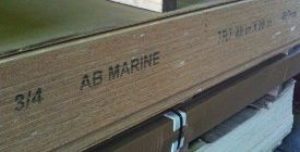

Marine Plywood Characteristics

All marine plywood will be free of voids in the core. Voids are traps for water and will rot the product from the inside out. Repairs to the core plies are very few for this same reason. Weather and Boil Proof (WBP) glue must be used as well. This glue has been subjected to boiling water for more than an hour without delamination of the plies. This is where the standards stop so you can see there is a lot of room for variety that can effect what kind of product you get. Additional standards like BS 1088 and BS 6566 raise the bar quite a bit on what is allowed but these only add to the variety of products open to the general market. Species of face veneer and appearance, species of veneer core, core construction, and glue used will all effect how the finished sheet of marine plywood will behave in different conditions.

Marine Grade Plywood for Boat Building

In some ways it would make most sense for the plywood suitable for boat building to be the only plywood with a marine grade label. Alas this is not so. Water resistance, bending ability, and appearance are all key. The plywood is either expected to be a show face or at least a consistent face that can operate as a reliable surface for a decking veneer or fiberglass overlay. Weight is another factor to consider but all of these additional variables depend upon your specific construction needs. As far as water resistance, plywood that is BS1088 (or better) should be a must in order to ensure long term durability.

Exterior Plywood for Structures

While perhaps not as harsh an environment as on a boat, depending on where the structure is situated exterior plywood can take quite a beating. Many of the same parameters are in play but the water resistance does not have to be as key and often appearance is of much less importance because the plywood is used as a substrate for an exterior hardwood, softwood, or composite material. Usually seaside homes and commercial structures need to have have marine grade plywood, but many licenses can be taken to lessen the costs due to less harsh environmental conditions. Since the plywood is not submerged in water some voids are permissible and this is a major factor that can save you money when buying Marine plywood for an ocean front property.

This range of quality comes with a wide range of price tags so it is imperative that the buyer understand which of the many variables are most important and buy the product with the right match. Don’t go to your dealer and just ask for “marine grade plywood” or if you do, be prepared to answer a whole slew of questions. If your dealer doesn’t’ ask you these questions then buyer beware as you may be getting either a sheet of plywood that is overkill or will fall apart on you down the road. There are many factors to consider and this article barely scratches the surface of the myriad technical details that make up grades of marine plywood. They key is to know that not all marine grade plywood is created equal and it shouldn’t be. Ask questions when you go to buy and keep in mind the key elements you need for your project. A reputable dealer can help you get the right product, whether it is marine plywood or exterior plywood.

Learn more about the lumber industry: