J. Gibson McIlvain can handle your millwork needs from blueprint to finished product. We maintain a full line of millwork capabilities in house.

We have moulders, custom knife grinders, straight line and gang rip saws, band resaws, and trimming saws.

We also provide oil-based and water-based priming for mouldings. We can even provide storage facilities for your millwork to improve inventory control.

Our huge stock of hardwoods, and our knowledgeable staff can help you select the right species for your profile and project application.

If our current profile catalog doesn’t have what you need, we can create a custom profile to match your project exactly. Even the most difficult profiles for historical restoration or contemporary design projects can be matched.

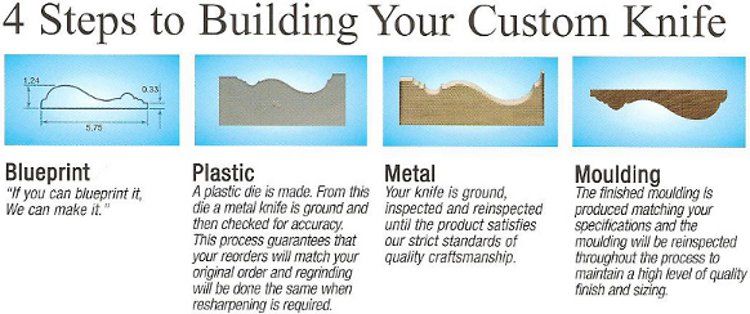

Our staff takes extreme care with even the smallest of details. Our grinders can make any straight steel or carbide knife required by your job. These knives are constantly resharpened during the process to provide even sizing and a quality finish throughout the job regardless of how touchy your wood species of choice may be.

Whether you need hardwood flooring, custom panels, architectural millwork, or mouldings, our millwork department can create it and ship it nationwide to your job site.

When you combine our millwork capability with our on site inventory of hardwoods, softwoods, and plywood, we are the obvious choice for your next custom millwork package.

Check Out Our Custom Moulding Profile Process