The availability of wider and longer African hardwood boards is much greater, the species are more durable and hold moulded details well. These are great species for millwork and flooring, but they are also very stable for windows and doors. Plus the large tree size means wider quarter sawn pieces for the door and window folks.

The African hardwood forests are well managed, and certification and verification schemes are widespread which make it very easy to track your lumber back to the stump to ensure legality and sustainability. It is exciting to see such a strong market stepping up to meet world demand at the time when the South American market is starting to falter.

However…

All is not rosy in the African lumber market. It is a very different import picture than South America with many different variables. For one, the African continent is rocked by never ending civil wars. The lumber market (among others) has been seriously depressed since 2008 globally, and buyers outside the United States have all but stopped buying. As a result, the African saw mills have scaled back production significantly to match this drop in demand.

Now, as the economic light at the end of the tunnel grows larger and global demand is on the rise, the African saw mills aren’t ready to meet that supply. Lumber production isn’t something that can be rushed, so ramping up production again to match the demand meets a bottleneck every time. Production is on the rise, but for now it is feasible to expect delays in shipments, while it’s common to find many mills trying to sell more of their odd sizes and off grade products to meet the demand.

The logs are felled deep in the forests, after which they are then floated or trucked hundreds if not thousands of miles to sawmills closer to the ports. A majority of those logs are not then sawn but rather exported in log form. Usually the logs are of a better quality as they are sold to veneer companies, plus the way logs are sold means the larger logs will net more profit.

Ultimately, the major cost increase of having the logs sawn onshore and the potential of running awry of Lacey legislation or another customs regulation means that buying sawn lumber is preferable. This does mean, however, that an additional hiccup is introduced into the supply chain. Most of the rivers reach a fall line above the port cities, where floating logs beyond that point is impossible due to rapids. From here, the logs have to be trucked further downstream to a sawmill in the port city. This requires trucking on very unreliable roads and can usually add as much as 2 months to the transport time.

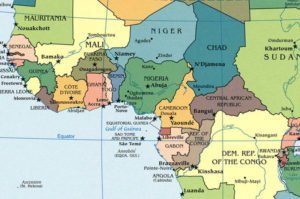

Where things get really hairy is that throughout this transit, the logs/lumber often cross multiple areas of conflict. Civil wars in the Central African Republic, the Congo, and Democratic Republic of Congo (among others) cross lumber supply chains. As a result, some areas are not producing lumber at all, while others in safe zones cannot transport the lumber to the ports in Cameroon or the Republic of Congo without running the risk of unsafe roads and hijacked trucks.

Despite all of these bumps on the supply road, African forestry companies are on their game. There is a strong sense of responsibility for the resources long term, and as mentioned above, the traceability from lumber to stump is outstanding with some strong certification and verification schemes.

On the whole, the African market is much, much bigger than the South American market, so there is more opportunity for companies like J. Gibson McIlvain to shop for good quality, sustainability, availability, and cost. The potential of monopolies which exist in some South American species is very small in Africa, making the whole African hardwood market to be very appealing for the future. But, as demonstrated above, no market or product is without problems.

Our African buyer is at the top of her game and has built strong relationships with many saw mills, and we are fortunate to be able to maintain a strong supply on the ground at our lumber yards. This way we hope to ameliorate cost spikes due to transit delays from all of the above factors.

Next time you cut into a Sapele or African Mahogany board, take a minute to reflect on just how many obstacles that board has passed through on its way to your saw.

Leave a Reply