In the past year we have upgraded our inventory software and hardware, added new lumber storage, and added new trucks to our fleet. This week we are taking another exciting step forward that will not only make us more efficient but it will ensure greater line of sight into our inventory and be able to increase the accuracy of our shipments outbound to you, our customers. This week with a new building completed to house it, we are installing our Vision Tally system that scans a pack of lumber and gives us a piece count and complete details of length, thickness, and width in no time.

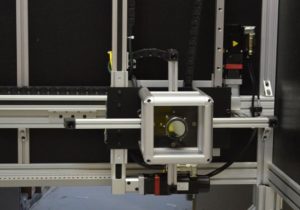

Vision Tally is a laser scanning system that uses two highly powerful cameras to scan a pack of lumber from both ends at once. The high powered lasers are able to penetrate the pack and obtain highly accurate measurements and volume in about 2 minutes. The reports generated are highly detailed and this information will sync with our inventory software giving us close to real time understanding of the lumber in every pack.

Trucks roll down the hill to our yard every day loaded with new material. Some may have come from Pennsylvania and others all the way from Thailand or Brazil. At the same time we are loading our own trucks and common carrier trucks for outbound customer shipments. All the while forklifts are running packs back and forth from kiln to air drying yard to sheds to mill to grading conveyor. It can be maddening to keep track of it all. Vision Tally will simplify a lot of this by capturing the exact details of every inbound shipment as well as each time the lumber is “transformed” (air dried to kiln dried, rough to S4S, etc). In this way we can actually map the progress of a single stick from the port to the customer if we need to.

Knowledge is power and if we can tell a customer that calls in if the material they need is in stock right away this will only improve our ability to satisfy their needs. Moreover we now have a quick way to validate what we have from our overseas sawmills since these shipped by volume alone and the individual piece details are not captured. Finally as the lumber or millwork is loaded to be shipped to you we can generate a highly accurate tally and graphical representation of the material so you know you are getting exactly what you ordered.

Needless to say we are thrilled to be able to take this step and are confident it will dramatically increase our ability to service our customers. Of course with such a high powered laser I’m wondering if I can cook hot dogs with it or what the potential of adapting it to energy/matter transfer for possible instantaneous lumber delivery.

…then we would need to hire someone named Scotty to run it.

Shannon, Very nice job with this write up. Thank you for the positive exposure.

Walt McIlvain