Lately we have been running into a lot of wide plank flooring jobs. In high end remodeling and construction, these 12″ and wider planks are a popular choice. But really anything larger than about 4″ wide could be considered wide plank in comparison to the typical “strip” flooring products. In other words, “wide plank” is kind of a relative term. Proportionally speaking, the bigger the room the wider the planks need to be to look “right”, unless you are looking for that bowling alley appearance. The latest trend in reclaimed flooring and rustic flooring also plays nicely into this as many wide boards are available for a truly one of a kind appearance. There is no question, these wide plank floors are stunning but they can be tricky to obtain and mill, and movement issues mean extra care must be taken to ensure a flat floor over time.

Choose Your Wood Species Wisely

When you start dealing with 8-12″ and wider flooring your choice of wood species becomes limited. While just about every species will yield a board over 12″ wide, getting the quantity needed for a large floor is the issue. Even if the quantity can be had, it will require picking from many different trees resulting in a difficult color and grain match. Make sure you or your client prepare for some inconsistency in appearance or you are prepared to apply a finishing technique that will color and blend the boards together. A good example of this is Walnut flooring. Walnut is a very popular species and who doesn’t love the deep chocolate tones and pleasing grain patterns. The issue is that Walnut is not a very hearty tree and you are lucky if you can get 1 or 2 good wide boards at a time. Moreover it is prone to a lot of defects so clear lumber is even harder to get in wide widths. As a rustic flooring product it would be easier to deal with, but the width issue remains. Finally, shorter lengths of flooring is a necessity in order to get the width you need. We often recommend Wenge as an alternative for a dark colored floor as wide planks are much easier to obtain. Alternatively, a stain application may be your solution. Regardless, additional work/cost will be necessary due to inadequacies of the chosen species.

Milling with Movement in Mind

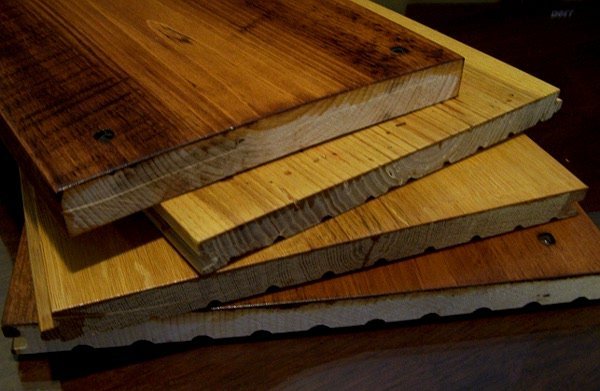

By it’s very nature, a wide plank usually is a complete cross section of a tree. The boards are flatsawn for the maximum width yield. Additionally the wider boards come from near the center of the tree to take full advantage of the total trunk diameter. This means you will get two edges with very stable quarter and rift sawn grain, but in between you will have the highly volatile pith or center area of the tree. The quartersawn material will expand and contract with moisture changes across the thickness of the board, but the central area will expand and contract directly across the width of the planks. So in essence this central area acts like a hinge where the outer stable wood will cup around it. Obviously the more quartersawn grain you can get into the plank the better the stability, but there is no way around the pith area unless you reduce the overall width of the board. To deal with this, careful drying of the wood is key and slow and steady milling and re-milling to allow for acclimatization of the wood. Flooring boards are usually joined either by ship lap or tongue and groove. With wide planks, the tongue and groove is the best option because the groove “traps” the tongue of the adjacent board to prevent it from lifting up and producing an uneven floor. Modifications to this joint can allow for some movement while keeping everything in the same plane and this is why it is essential for your wide boards. In the end, careful sawing, drying, and careful milling will get good quality boards to your job site but the real success comes from proper installation.

Installation with a Long View in Mind

When installing a wide plank floor, you have to think about what changes the wood will undergo throughout the entire year. The first thing to consider once the flooring is delivered to the job site is proper acclimatization. The wide planks should be stickered and allowed to come into equilibrium with the room where they are to be installed. The time to allow for this can vary depending on the room environment and how far the flooring traveled from supplier to job site so consider each situation individually and consult your supplier for advice. Also consider your sub floor. Depending on what you have, different techniques need to be employed to fasten and control moisture. The tongue and groove joint will allow for movement across the width as long as an expansion gap is left between the boards** Make sure your client is aware that the gap is necessary and it will close or open up at certain times of the year. Most T&G patterns allow for an undercut shoulder on the tongue side where the plank can be toe-nailed to the sub floor. This will anchor one side of the board and push the movement to the other either closing or opening that gap with the other board. If the client does not want to see any gaps then another option is to leave the entire floor floating that will expand and contract as a single unit. Now the expansion gap needs to be at the edge of the room and can be covered with a shoe moulding. A floating floor can still cause problems where unevenness and buckling may creep in since not all the boards will move the same amount or in the same directions.

**Depending on the time of year the installation may require the boards to have no gaps or some gaps since summer months are more humid than winter months**

The ultimate solution is to install a humidity control systems specific to the room where the wide flooring is installed. This is obviously the most expensive solution but considering the investment in the material and the possible size of the room, it might be the most wise thing to consider. These systems are often used in clean room and laboratory environments where conditions must be maintained at all times. While conditions need not be as strict for your average household, these systems will maintain a constant moisture level all year around and keep the floor in constant equilibrium eliminating almost all movement.

With so many things to consider, one can quickly see why this flooring is usually not seen outside the most expensive homes, but the popularity is growing and if done right, a wide plank floor can truly be stunning. Careful planning and above all a top notch supplier that understands wood species limitations, movement, and installation issues is a must.

Learn more about the lumber industry:

Leave a Reply