One thing that is difficult when working with wood is the range of colors you find within a single species. All woods will change color throughout the process from sawmill to finished project. Wood continues to change color years down the road. It fades in the sunlight, but some woods also undergo chemical changes that change the wood color. The one thing you can count on is the color will change. Additionally, expect that matching an existing wood may take months or years to do as the wood ages. Let’s look at a few common examples.

Do You Have Gray Decking?

We often have customers who approach us looking to match a color of a floor or table. Sometimes they are specifically looking for an exterior wood that will turn gray to match an old deck or pergola. This scenario is easy, since any wood left exposed to the elements weathers to a silvery gray. The outer layer will keep this gray coloring until it is cut, sanded or planed.

Some woods go gray faster than others. You will find that the oily species like tropical decking fight this graying for a long time. Essentially, the sun is bleaching the surface and drying the oil. Any extra resin or oil in the wood resists this action; and of course, when you add oil to the surface as regular maintenance, you are preventing the bleaching. Keep that in mind whenever you hear about a maintenance free deck or exterior product. These are maintenance free only if you don’t mind them going gray.

Sunlight Dries Out and Fades Everything

Additionally since the sun is drying the wood, you can expect to see tiny surface cracks. They are called checks. Checking doesn’t always happen, but in really intense sunlight, these tiny surface cracks are pretty inevitable. It is not a defect in the wood. Actually it is a coping mechanism when wood is forced to dry quickly and unevenly.

Really, finding a color match is just a matter of waiting for nature to do your job for you. The species used and the amount of sunlight it gets will change the time it takes, but eventually the wood will go gray. There are bleaching oils available that will speed up this process, but I have found it falls short of the same look. The reality is that this naturally weathered look is a combination of heat, water, wind, UV light, and longer wavelength light; just applying a chemical bleach won’t match the work that mother nature can do.

I Want that Cherry Wood Color

When we bring the wood inside and protect it from the element, it still changes color over time. This is most obvious when a board is first milled and appears lighter than a board cut a few hours earlier. Later on as we apply some kind of finish to the wood, the color changes to darken the surface. The finish continues to react with the wood long after it cures to change the color of the wood.

So the “cherry finish” request is a lot tougher to meet than you might expect. It isn’t possible without a lot of chemical help and time. Cherry is a light pink color when freshly milled. However the famous Cherry finish is a deep, dark red. Cherry doesn’t actually look like that when left to its own devices. It usually ends up looking more brown than red. It is stain or dye and years of dirt that creates that dark red coloring that so many falsely associate with Cherry.

Furniture makers today tend to go heavy on the dye to get this color. Some makers may not even be using actual Cherry under all that coloring. The problem with adding all this color up front is that the color will continue to change over time underneath and in reaction to the finish applied. This means your eventual end color may not be what was intended.

So what is going on to affect this color change, even if it is kept out of the elements?

Extractives and Lignin drive Color Change

The chemical components of wood are very complex and highly variable depending on the species and where the tree grew. There are a few chemical component types that make the biggest difference: Lignins, and wood extractives. Lignins are water resistant compounds that bind the cellulose wood fibers. They are the glue in the structure. Extractives are more exotic compounds. They are “extracted” to make other products like Turpentine or pharmaceutical products. Wine lovers are big fans of extractives. Tannins are a subclass of the extractives common in Oaks that are essential to making wine and whiskey. This is why barrels are made from Oak always.

Both Lignins and extractives play a major role in the color changes that occur in the longer wavelengths light we find in homes. They react and break down when in contact with heat or the other chemicals like varnishes, lacquers, or furniture waxes. While the tree is still alive, these compounds are largely responsible for the color change that occurs when sapwood is converted into heartwood. These compounds continue to work from the minute the wood is sawn throughout its lifespan. You could sand an old table back to the raw wood from which it was made 300 years ago, and these compounds would start reacting again with the air and light to start to darken the wood.

It is these compounds that cause dramatic color changes in all species but some more than others. Purpleheart freshly milled has the purple color but changes to a brown color as the extractives react to the air. It is something of a surprise to the individual who chose Purpleheart for that color.

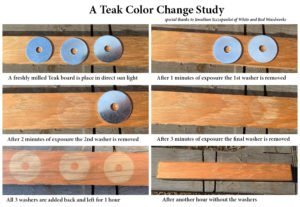

Teak is infamous for this color change due to the extremely high oil and silica content (both extractives). This is what makes it so exceptional as a marine construction material but what also what wreaks havoc with designers going for that lovely honey brown look. Teak comes out of the planer streaky and multicolored like a child’s finger paint gone horribly wrong with greens, purples, and grays and not a hint of honey brown.

Mahogany, the king of furniture woods, starts as a very light pink and quickly turns reddish brown with exposure. This process continues over time but never really gets as dark as the antiques we see in museums until decades of dirt and chemical reaction make it that dark. This list goes on and on and touches just about every species of wood.

The Solution: An Intentional sun tan

This is frustrating but also exciting, because wood is unique and unpredictable. This is what makes wood so beautiful. But unique is also what makes us realize that color matching is just about waiting for it to change on its own.

The best thing you can do is give your wood a good sun tan before any finish is applied. Furniture makers often will set pieces out in bright sunlight for a day. When you consider hardwood flooring or interior trim work, color may change unevenly based on the amount of sunlight they get. Look no further than underneath your area rug to see how flooring colors change.

The point to all of this is that wood color is not a static attribute. It can take years or decades to settle down. Much like wood movement due to climate change, wood color is something we have to anticipate and plan for; however, we sometimes have to accept that we don’t know what will happen. We just embrace it for the unique and wonderfully organic building material that it is.

Learn more about the lumber industry:

Leave a Reply