Take a Deep Breath

Natural Toxins

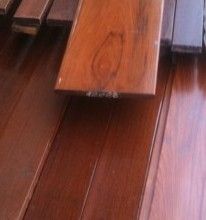

Tropical woods boast great beauty and durability, but they can be some of the worst offenders. Not only are they very dense meaning more fine dust is produced with cutting and drilling them, but their natural insect and weather resistance is because of chemicals in the tree during growth. Think of these chemicals as a natural pesticide. It keeps the bugs away while the tree grows, and while the wood adorns your deck. Now think about what gets atomized and blown into the air every time you cut into that wood.

The weather resistance of many tropical species is often a product of the natural oils present in the wood. (oil and water don’t mix) Those oils also are ripe with these same chemicals and as the oil rubs off on your skin the chemicals come with it. I have seen woodworkers break out in a rash within minutes of coming in contact with an oily wood. Obviously this is extreme, but remember that all allergies can develop over time when prolonged exposure occurs.

Another element to consider is if you are naturally allergic to certain pharmaceutical products. Many medicines are derived from botanicals and the chemicals that comprise those medicines are found naturally in the wood. When skin contact or more commonly, breathing in those chemicals occurs, the same allergic reaction comes into play. The most common example of this is those allergic to Aspirin. Salicylic acid is the key ingredient in Aspirin and it also happens to be present in large amounts in Birch and Willow trees. Many pharmaceuticals rely on fungal spores and these same spores can grow in fallen trees. What a woodworker prizes as a spalted species for great figure and color can actually cause an allergic reaction when worked.

Man made toxins

Of course being the tinkerers that we are, man has done our share of introducing chemicals into the wood we work. Any pressure treated wood contains arsenic among other nasty elements in it’s cocktail. Composite products and plywoods often have levels of formaldehyde that can cause problems while being worked but also afterwards as off gassing occurs. Green initiatives are under way to drastically reduce these levels but they are still present and must be considered every time they are used.

Enough scare tactics already

You should already have one that you don when you apply your favorite finish anyway right?? (that’s a topic for next year)

Nothing beats preventing those malicious little particle from getting to your lungs in the first place than a good respirator that can be had for $20-60. Safety doesn’t have to be expensive. Long sleeves and gloves can prevent skin irritation if that is a problem for you.

Overall look for the red flags and consider safety precautions.

- Very Dense woods = fine dust particles

- Oily woods

- Weather and Insect resistant woods

Every wood can cause an irritation over time and each person may react differently. Any time a new wood species is brought into your shop pay attention to how you and the people around you react to it. You may have an allergy you don’t know about so it is best to just keep that respirator nearby to be safe.

If someone gives you a hard time, then send them to this blog post and ask them who is taking the bigger risk. It is nothing to worry about if you take the right precautions, so be safe and enjoy making beautiful things from your favorite wood species.

For more articles on safety, tune in to all the Woodworker’s Safety Week links at The Wood Whisperer.com

or…

Google “Wood Dust MSDS” for any number of Material and Safety Data Sheets for more information that any one person can retain.

Leave a Reply