As if it were some kind of perpetual motion machine, wood will never stop moving. No matter how old it is, what has been done to seal it, fasten it, or restrain it, the wood will move. Accept it, and move on. Understanding how and why your wood moves is necessary if you are going to work with this wonderful medium. Understanding how a particular species and cut moves is even more important when it comes to figuring out the tolerances you have to work with.

Think of wood as a bundle of straws. While it grows, trees suck up moisture from the ground into these straws and transports the water and nutrients throughout the tree to help it grow. When a tree is cut down and sawn into lumber these straws are still full of water but will start to shed that water from the ends of the straws. As the straws lose water they shrink and become narrower. Conversely they grow as they take on moisture. This process will continue until the wood comes into equilibrium with the surrounding humidity. Loss and absorption of moisture can be controlled and slowed through end sealing, finishing, kiln drying, and more but nothing can stop it entirely. This expansion and contraction of the straws is what causes wood movement. The only way to deal with it is to anticipate the movement and build accordingly.

Each and every wood species page on our site has a chart with technical data in it that can help you decipher how a species will perform in a variety of condition. The most important data in those charts when it comes to movement is tangential shrinkage and radial shrinkage.

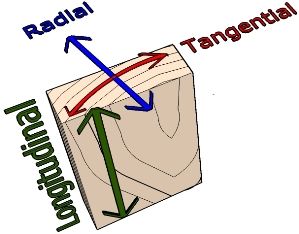

Tangential shrinkage is the amount the wood moves along the growth rings. Imagine this as the side to side swelling of those straws. This is the greatest amount of movement lumber experiences.

Radial shrinkage is the amount the wood moves perpendicular to the growth rings or along the radial or medullary rays that transport nutrients into the interior of the tree. This is a small amount of movement but still should be accounted for.

**It should be noted that wood will move along the length of the board but this is very minimal and for the most part can be discounted.**

If you take the ratio of tangential versus radial movement or T/R ratio you can get a good feel for how stable a species is. The closer these numbers the less the board will have a tendency to warp and cup.

Now we understand that wood moves, why it moves, and that different species move different amounts. Knowing this we can allow for the movement and make sure our decks, windows, siding, flooring, etc don’t explode as the humidity rises and falls throughout the year. The real rub is that the wood we use does not expand and contract uniformly. Going back to the straw analogy: if the moisture is lost from the ends then obviously the ends will dry out faster than the middle. It is this differential that causes wood to bow, cup, twist, and warp. To avoid this time must be allowed for the slower parts of the board to catch up with the faster parts. Every time a pack of lumber is moved from one part of the country to the other or even as simple as from the cool shade into bright sunlight, the lumber goes through an adjustment period where warpage can occur. Eventually the entire board will reach equilibrium and the exchange of moisture will slow (not stop).

Our job is to lessen these wide swings of moisture. Don’t leave your lumber in direct sunlight where the heat will accelerate this moisture loss. Stack your lumber in a well ventilated area and perhaps even sticker the wood (insert small pieces between the boards that allow air to flow through a pack) so that even drying can occur. Most important is to simply give your lumber time to acclimate to it’s new surroundings. Preferably also following the above advice and letting that acclimatization happen in a friendly environment.

As a woodworker, builder, manufacturer or whatever, you will mostly be using kiln dried lumber; so much of the work is already done for you by us. The wood will be more stable once it is kiln dried to a uniform moisture content, but it will still move if mistreated. J. Gibson McIlvain ships our lumber nationwide and when we move kiln dried Mahogany from the humid summer months here in Maryland to the dry and hot desert of Arizona, that Mahogany is going to move. Should it be cut up and moulded or built into a fixed position before that movement has had time to equalize, it can get ugly very quickly.

In summary, wood is an organic material that will always move as long as the humidity changes. There is nothing you can do to stop it so understanding is a must to be able to work with it. Accept it, respect it, and deal with it and love it.

Learn more about the lumber industry:

This article really strikes home. Being in the antique boat restoration and sales business, we constantly have to tell customers that “it is wood, not fiberglass. It moves”.

I would appreciate it if you would give me permission to reprint this article for some of our customers.

Of course Joel, happy to help. I would appreciate it if you keep the J Gibson McIlvain name attached to it but other than that go for it and let us know if we can answer any additional questions.

I am from Brazil and i am graduating in Forest Engineering, i have some works based in shrinkage and swelling of wood, im drying wood in several temperatures, in the end i will see what temperature is better to dry a wood for it is not gain much water, so it will be more stable

Hi Shannon – we bought a large Timberframe home a year ago. It is 25 years old. I love the cracks in the beams but there is also twisting on a few of the vertical beams. Will this affect their structural integrity?

Not in the slightest. No worries and enjoy your timberframe, they are gorgeous.