Red Oak Lumber: the Durable Flooring and Cabinetry Choice

Quercus Rubra

Red Oak wood, like most of the North American Oaks, is very hearty and grows quite large, which results in high availability and affordable pricing. Red Oak lumber is best used for interior hardwood flooring and cabinetry. It is often found in pallets as well as in staircase construction due to its open grain structure that allows for easy bending.

| Character | Green | Dry | Units |

| Bending Strength | 8750 | 14050 | psi |

| Crushing Strength | 695 | 1140 | psi |

| Max Crushing Strength | 3665 | 6900 | psi |

| Static Bending | 4200 | 8300 | psi |

| Impact Strength | 54 | 50 | inches |

| Stiffness | 1440 | 1755 | 1000 psi |

| Work to Maximum Load | 15 | 15 | in-lbs/in3 |

| Hardness (Janka) | – | 1290 | lbs |

| Shearing Strength | – | 1780 | psi |

| Specific Gravity | 0.57 | 0.64 | – |

| Weight | 63 | 43 | lbs/ft3 |

| Radial Shrinkage | – | 4 | % |

| Tangential Shrinkage | – | 8 | % |

| Volumetric Shrinkage | – | 13 | % |

Red Oak Wood Stain and Finishing

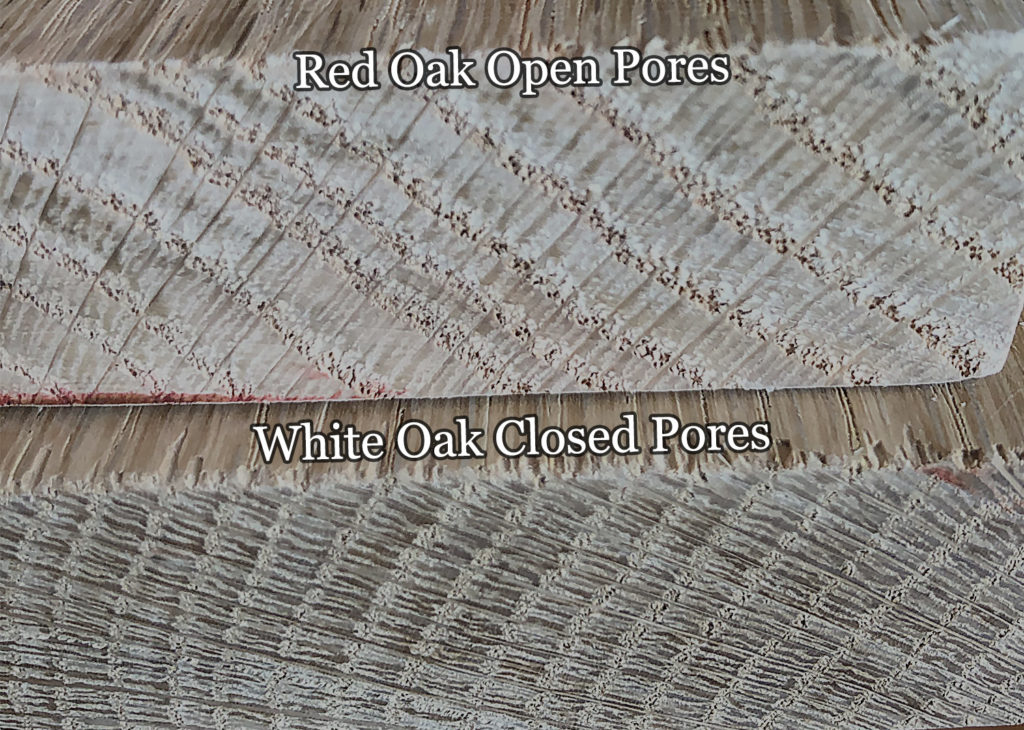

It should be noted that due to its high level of tannins, Red Oak will corrode steel fasteners; this can then cause staining of the wood over time. This same staining can occur when water-based glues and steel clamps are used, so care should be taken during assembly to avoid these products. Because of open pores and grain, Red Oak will finish well, but a uniform surface can sometimes be hard to obtain without a pore filler. Red Oak wood will stain nicely, however, because it has so many pores to capture and hold pigment.

With its availability and low cost, Red Oak lumber is used in a wide range of applications. Red Oak is commonly used by retail stores for shelves, moulding, and merchandising fixtures. Most often, Red Oak wood is the standard in hardwood flooring, and J. Gibson McIlvain carries a large volume of Red Oak specifically in rift and quarter sawn cuts for flooring. We can also produce millwork with our on-site facilities to match any blueprints.

Red oak vs white oak

Telling the difference between Red Oak and White Oak can be difficult as they are very similar. Certainly Red Oak has a reddish tinge to it, especially when freshly cut, but this fades as it dries and ends up looking almost identical to White Oak. White Oak will have more brown hues to it, but it gets its name actually from the color of the bark on the tree. White Oak trees have shaggy bark with a very light color, making them stand out in the forest; as a result, White Oak trees often have been called “ghosts of the forest.”

The primary difference between Red Oak and White Oak is the pore structure. Red Oak has open pores that will absorb water, while White Oak has closed pores stuffed with a substance called Tyloses that repels water. This difference is what makes White Oak a great wood for exterior furniture and siding, while Red Oak remains only suited for interior applications like cabinetry, furniture, and flooring. Red Oak wood is also softer than White Oak but not by much with a Janka hardness of 1290 vs 1360. Both are known to be very strong woods, and this is why they are both commonly used in hardwood flooring. Because of these similarities, the price of Red Oak and White Oak is similar and mostly dependent on supply and demand, but only differing by a small amount.