I have written briefly about how Walnut lumber is graded differently from other North American hardwoods, but it seems that customers are still surprised by the apparent lack of quality in Walnut lumber. Usually these inquiries are met with surprise on the part of our grading team, as our graders were quite proud of the quality of Walnut that left our yard.

I have written briefly about how Walnut lumber is graded differently from other North American hardwoods, but it seems that customers are still surprised by the apparent lack of quality in Walnut lumber. Usually these inquiries are met with surprise on the part of our grading team, as our graders were quite proud of the quality of Walnut that left our yard.

What it really comes down to are two different expectations of what “good quality” Walnut actually is. So let’s break it down according to NHLA (National Hardwood Lumber Association) guidelines and compare Walnut to the rest of the typical North American hardwoods. The actual grading rules are pretty complex, so I’ll see if I can simplify things and compare Walnut to some of the other hardwoods which we carry.

Black Walnut Lumber Grade

For more information on NHLA grading and defects, be sure to check out Understanding Hardwood Lumber Grades.

Grade: First and Seconds (FAS)

This is the highest grade, and NHLA states for all lumber the following:

- 83.3% clear of defect on both faces

- Minimum Board Size: 6″x8′

- Minimum Clear Cutting Size: 3″x7′ or 4″x5′

Now for Walnut lumber, the rules are changed, and the bar is lowered to allow a wider sample of wood into the grade. The above guidelines are the same with the exception of the following changes:

- Minimum Board Size is reduced to 5″x6′ with 80% of the pack yielding 8′ and longer

- Minimum Clear Cutting Size is reduced to 4″x3′ or 3″x6′

- Pieces 5″ x 6-7′ are allowed wane along the edges, splits not longer than 6″ on 1 end, and 1 defect

- Pieces 8″ and wider are admitted 2 defects

Grade: Selects

This grade is very similar to FAS, but now both faces do not have to meet the grade. The standard grading rule for all species is:

- 83.3% clear on 1 face only with the 2nd face being of #2 Common grade

- Minimum Board Size: 4″ x 6′

- Minimum Clear Cutting Size is the same as FAS but for 1 face

For Walnut, again the rules are changed as follows:

- Minimum Clear Cutting Size: 4″ x 3′ or 3″ x 6′

Essentially, the rules for Selects Walnut are the same as FAS, but again only 1 face must meet the grade and the other face must meet #1 Common grade.

Grade: #1 Common

The Common grades are much less in demand for most species, which is a shame, because as you will see there is still quite a bit of usable lumber in each board. Usually being able to work with and around knots will make you a great customer for Common lumber. The standard grade is:

- 66.6% clear on both faces

- Minimum Board Size: 3″ x 4′

- Minimum Clear Cutting Size: 3″ x 3′ or 4″ x 2′

For Walnut, again the guidelines are the same with the following exceptions:

- Minimum Clear Cutting Size: 3″ x 2′

Again, the cutting size has been reduced, yet the percentages remain the same, which basically means smaller boards can be admitted into the grade.

Grade: #2 Common

While there are grades below this, most view this as the lowest grade, and boards that do not meet it are usually designated for other uses like pallets and other utility purposes.

- 50% clear on the better face

- Minimum Board Size: 3″ x 4′

- Minimum Clear Cutting Size: 3″ x 2′

If you look closely, though the clear cutting size vs the minimum board size are quite similar (which means on 1 face you can have a very nice board, albeit small), so this is often the grade of choice for hardwood flooring manufacturers where narrow boards are desired for stability and only 1 face is ever seen.

In Walnut, #2 Common isn’t much different with 1 exception:

- Minimum Clear Cutting: 2″ with no length restriction

This does make #2 Common Walnut almost unusable for anything but very specific things where small pieces are needed or where defects are welcome such as rustic applications.

So why the Lower bar for Walnut Hardwood?

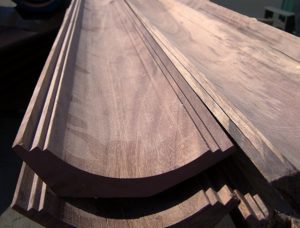

These defects and smaller boards are just the nature of Walnut. The tree just grows this way with many branches and a lot of twisted and contorted grain. With the stark contrast between sapwood and heartwood, more attention is paid to removing it, yet the sap layer can be quite large in Walnut. Personally I love this contrast even in unsteamed Walnut (steaming helps to homogenize the color difference), but it is hard to achieve a uniform look in a project with sapwood.

Despite (and maybe because of) all these things, Walnut remains one of the most sought after North American hardwoods. It has long been the king of cabinet woods, it is prized for flooring, and it is even highly desired for millwork projects. Because of this demand, the grading systems loosened the guidelines in order to promote wider usage of the species. This was a very wise decision indeed, because when the saw meets the wood in your project, think about just how much of the wood is cut into various parts. Think of all those little off cuts that end up on the shop floor. With some planning, you will find that cutting around these defects or starting with a narrower and shorter board is not such a bad thing after all.

Remember, though, that grading systems set the minimum allowable standard. There will always be better than grade lumber, and we recognize that many customers demand and require even better quality than the rules state. If this is the case, you can expect additional costs associated with pulling and sorting your lumber. If we have to pick all the above grade from a pack, the whole remaining pack becomes devalued, so pricing may need to cover this as well.

So here we stand in a familiar lumber paradox: pricing is way up on Walnut, but quality is still perceived as way low. But is it really? Walnut grading standards have been in place for a long time, and lumber mills have been meeting that grade all that time. Walnut will never meet the same quality as species like Maple or Oak or even Cherry. The key to consider is the minimum allowables on the grades and what you are actually getting. Clear two faced Walnut is really at a premium, but single face is a lot more reasonable. Still we often supply our customers with sizes that far exceed what actually meets the grade according to NHLA.

What you need to consider is do I need Black Walnut lumber that is better than grade?

Learn more about the lumber industry:

I know these articles are intended more for a commerical audience. As a hobbyist, I love the wild grain and “defects” inherent to walnut. I only buy unsteamed walnut because, with a nice finish, the sapwood takes on a pearlescent quality I have not seen in any other species. I built a book-matched table top with a cone shaped section of sap straddling the glue line. Everyone comments on it and immediately touches the sap, expecting it to be an inlay of some sort. So for all the commercial buyers who can’t or won’t tolerate the character of walnut, I say “more for me.” 🙂

But it does beg the question: Are there any exotic substitutes that provide a medium/dark brown, straight grained, clear lumber? If so maybe people should look in that direction for mill work and cabinet lumber.

Mike, I’m with you on the unsteamed Walnut, but as you know that is some hard stuff to find. The overwhelming demand is for steamed so it is very hard for a mill to make any money on the unsteamed stuff. Believe it or not the chocolate brown color of Walnut is pretty rare in the world. Peruvian Walnut (Nogal) is an option and it does grow in much bigger sizes. The thing is no matter the specs, an exotic will always be more expensive just because of the import costs and additional regulatory costs.

Is a Black Walnut board still FAS with 1 clear Face and the other has Saddleback wane Still FAS.

Ex. 7″ wide board with only 2″ seperating the wane?

It depends on how long the board is but, yes, a board over 5″ wide is allowed wane. Especially considering one face is clear.